see how its done

if you can't get down to Wales to visit us, scroll down and you can still see all the manufacturing process and how we design and weave the fabrics here at the mill

see how its done

see how its done

if you can't get down to Wales to visit us, scroll down and you can still see all the manufacturing process and how we design and weave the fabrics here at the mill

see how its done

Design

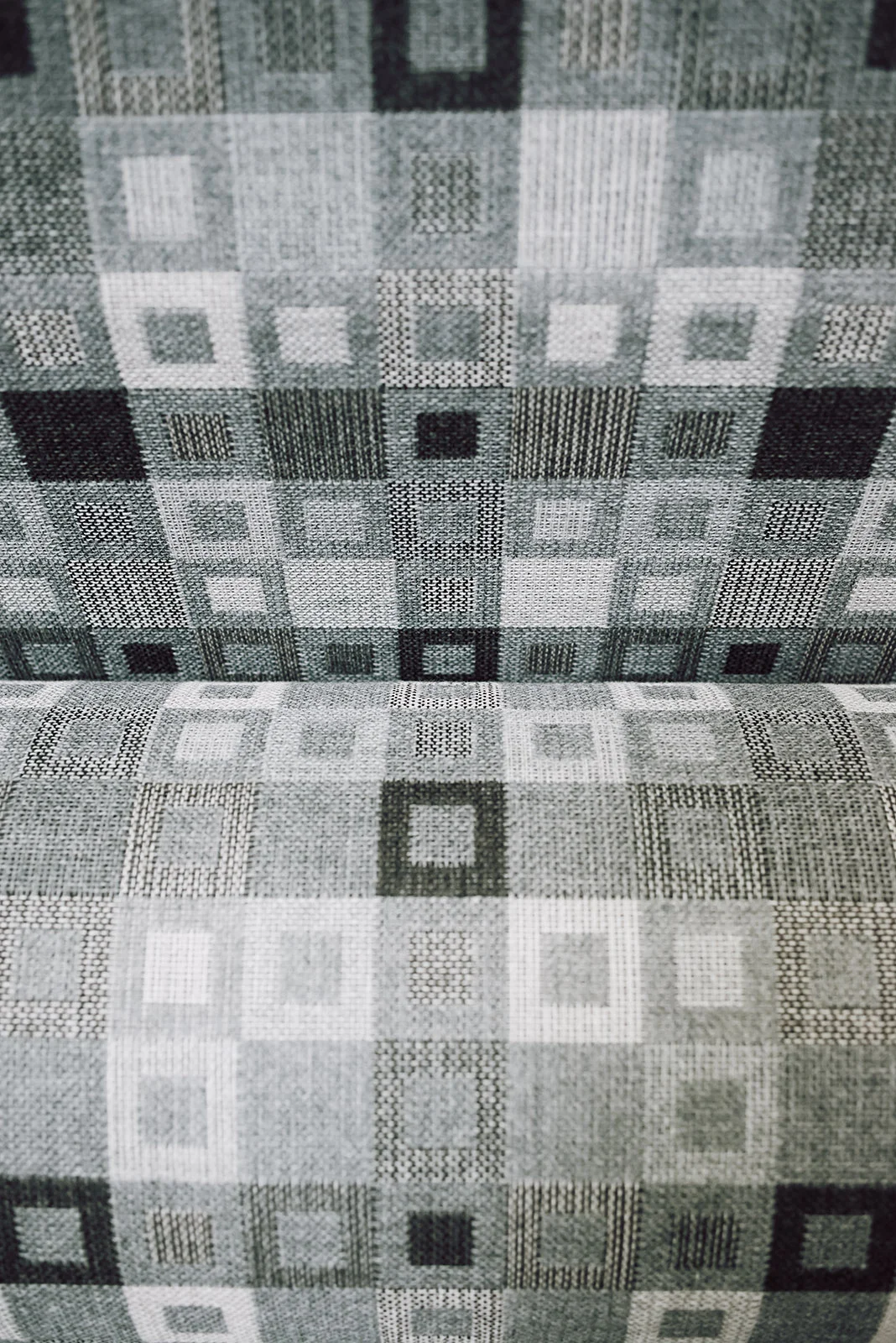

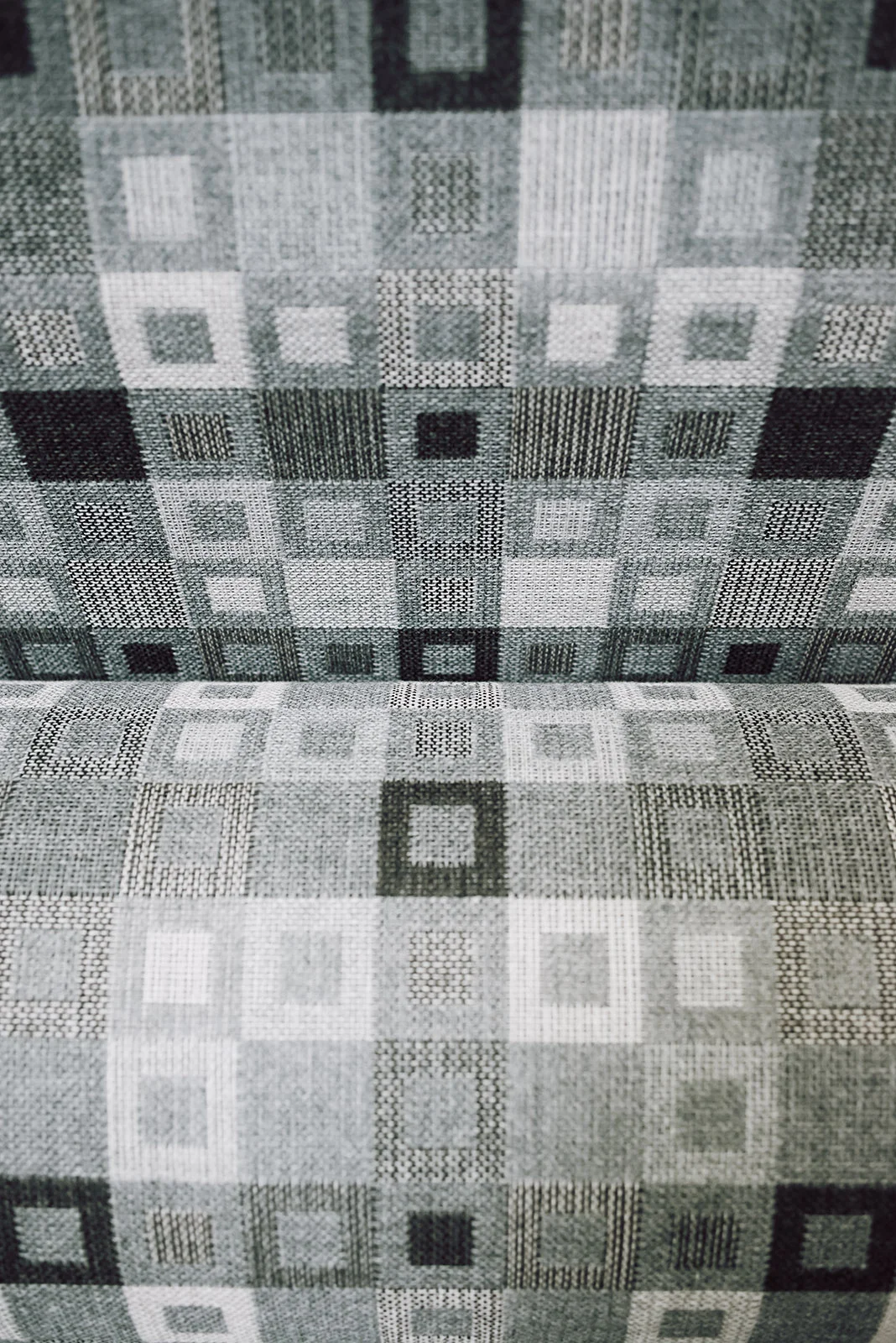

Melin Tregwynt specialise in doublecloth and most of our fabrics have strong graphic designs with a retro, mid-century modern quality. In addition to our stock ranges we have worked with many companies who have commissioned exclusive ranges of fabrics, throws and blankets. We prepare CAD drawings, followed by handloom samples for approval, before a full run. Lead times will depend on yarns, number of colours, designs chosen etc.

Design

Melin Tregwynt specialise in doublecloth and most of our fabrics have strong graphic designs with a retro, mid-century modern quality. In addition to our stock ranges we have worked with many companies who have commissioned exclusive ranges of fabrics, throws and blankets. We prepare CAD drawings, followed by handloom samples for approval, before a full run. Lead times will depend on yarns, number of colours, designs chosen etc.

Loading Creel

To weave, you first need to create a warp. This consists of a number of threads lying next to each other that run the whole length of the cloth. Cones are set on the warping stand in a specific order of colours for the pattern of the cloth being warped for.

Loading Creel

To weave, you first need to create a warp. This consists of a number of threads lying next to each other that run the whole length of the cloth. Cones are set on the warping stand in a specific order of colours for the pattern of the cloth being warped for.

Threading In

Each doublecloth design requires a minimum of 16 shafts. Widths 150/200/230 are possible. Each shaft will require heddles (for yarn to pass through) of up to 2500 per warp depending on loom width, plus a reed to control the warp threads. These heddles will all have to be re-threaded for each new design. This is normally done off the loom. To put new threaded shafts back on to the loom (and take out previous set of shafts) is about a day’s work

Threading In

Each doublecloth design requires a minimum of 16 shafts. Widths 150/200/230 are possible. Each shaft will require heddles (for yarn to pass through) of up to 2500 per warp depending on loom width, plus a reed to control the warp threads. These heddles will all have to be re-threaded for each new design. This is normally done off the loom. To put new threaded shafts back on to the loom (and take out previous set of shafts) is about a day’s work

Warping

The ends of these cones are wound onto the warping wheel in sections of approx 200 threads each, to create the total width of the warp, (between 1600 and 3000 ends). Each turn of the warping wheel creates about 4 to 5 metres of warp. At the end of a set number of turns, the bell rings to tell the warper to move on to the next section of 200 threads.

Warping

The ends of these cones are wound onto the warping wheel in sections of approx 200 threads each, to create the total width of the warp, (between 1600 and 3000 ends). Each turn of the warping wheel creates about 4 to 5 metres of warp. At the end of a set number of turns, the bell rings to tell the warper to move on to the next section of 200 threads.

Beaming Off

Once the full warp has been created, it is wound off of the warping wheel onto a beam. The beam is then fixed on the back of the loom.

Beaming Off

Once the full warp has been created, it is wound off of the warping wheel onto a beam. The beam is then fixed on the back of the loom.

Tying in the Warp

If the loom is already set up with the desired ‘thread-up’, the new warp is tied on by hand to the old warp, using a ‘weaver’s knot’. The ends must be tied together in the correct order and under tension, for the design of the cloth to be woven correctly. Once the warp is set up on the loom, the cloth can then be woven (by sending weft threads across and through the warp). It is the combination of colour and structure that creates the varying designs of cloth.

Tying in the Warp

If the loom is already set up with the desired ‘thread-up’, the new warp is tied on by hand to the old warp, using a ‘weaver’s knot’. The ends must be tied together in the correct order and under tension, for the design of the cloth to be woven correctly. Once the warp is set up on the loom, the cloth can then be woven (by sending weft threads across and through the warp). It is the combination of colour and structure that creates the varying designs of cloth.

Lifting the shafts

The shafts lift up and down in a particular sequence to create the desired structure. These are controlled by a punch-card chain which tells which shafts to lift and drop. There is a corresponding chain that controls the weft, so that each ‘pick’ or weft thread is sent across the cloth in the correct colour order.

Lifting the shafts

The shafts lift up and down in a particular sequence to create the desired structure. These are controlled by a punch-card chain which tells which shafts to lift and drop. There is a corresponding chain that controls the weft, so that each ‘pick’ or weft thread is sent across the cloth in the correct colour order.

Weaving

Once the warp is set up on the loom, the cloth can then be woven (by sending weft threads across and through the warp). The weft is carried straight off the cone, through an accumulator by the left-hand rapier. This meets the right-hand rapier which catches the weft and takes it across the remaining width of the cloth. As the rapiers meet in the middle of the cloth, the weaving process is quicker and more efficient than weaving with flying shuttles. In fact, they move so fast it can be difficult to see them.

Weaving

Once the warp is set up on the loom, the cloth can then be woven (by sending weft threads across and through the warp). The weft is carried straight off the cone, through an accumulator by the left-hand rapier. This meets the right-hand rapier which catches the weft and takes it across the remaining width of the cloth. As the rapiers meet in the middle of the cloth, the weaving process is quicker and more efficient than weaving with flying shuttles. In fact, they move so fast it can be difficult to see them.

Completed cloth

The woven cloth is wound onto a beam at the front of the loom. This is cut out in 30-50 m. Lengths so that the cloth can be mended and finished.

Completed cloth

The woven cloth is wound onto a beam at the front of the loom. This is cut out in 30-50 m. Lengths so that the cloth can be mended and finished.

Mending

Mending – cloth checked both sides for any knots or imperfections, and all anomalies fixed/made as perfect as possible before finishing. Cloth is folded, rolled and packed before being sent for finishing (washed, brushed, pressed etc) at our finishers in Scotland.

Mending

Mending – cloth checked both sides for any knots or imperfections, and all anomalies fixed/made as perfect as possible before finishing. Cloth is folded, rolled and packed before being sent for finishing (washed, brushed, pressed etc) at our finishers in Scotland.

Cutting

Once woven and finished we store our cloth on 30m long rolls, every throw, cushion and blanket is cut by hand on our specially built 2.5m square table.

Cutting

Once woven and finished we store our cloth on 30m long rolls, every throw, cushion and blanket is cut by hand on our specially built 2.5m square table.

Sewing

Our lovely sewing ladies sew every hem, seam, zip and label before checking that each item is perfect before it starts its journey to its new owner's home.

Sewing

Our lovely sewing ladies sew every hem, seam, zip and label before checking that each item is perfect before it starts its journey to its new owner's home.